Liquid nitrogen vs dry ice comes down to their temperature, form, and industrial uses. Liquid nitrogen is a cryogenic liquid at -320.4°F, while dry ice is solid carbon dioxide at -109.3°F. Though both are used for extreme cooling, liquid nitrogen is colder and better for cryopreservation, while dry ice is favored for shipping and fog effects.

Dry ice and liquid nitrogen are both highly effective cooling agents widely used in various industries. While they share some similarities in their cooling capabilities, they also have distinct properties and applications.

In this comprehensive guide, Subzero Dry Ice will explore dry ice vs liquid nitrogen, their similarities, differences, uses, safety considerations, and how to choose the right one for your needs.

What is Dry Ice?

Dry ice is the solid form of carbon dioxide (CO2). It is extremely cold, with a temperature of -109.3°F (-78.5°C), and sublimates directly from a solid to a gas without passing through a liquid phase. This property makes it an ideal cooling agent for applications where moisture is a concern.

Properties of Dry Ice

- Temperature: -109.3°F (-78.5°C)

- Phase Transition: Sublimates directly from solid to gas

- Density: 1.56 g/cm³

- Common Forms: Pellets, blocks, slices

What is Liquid Nitrogen?

Liquid nitrogen is nitrogen (N2) in its liquid state, maintained at an extremely low temperature. It boils at -320.4°F (-196°C) and is commonly used for rapid freezing and cryogenic applications.

Properties of Liquid Nitrogen

- Temperature: -320.4°F (-196°C)

- Phase Transition: Boils from liquid to gas

- Density: 0.807 g/cm³ (at boiling point)

- Common Forms: Liquid stored in insulated containers (dewars)

Comparison of Dry Ice and Liquid Nitrogen

To understand the differences and similarities between dry ice and liquid nitrogen, let’s compare their properties, uses, and handling requirements.

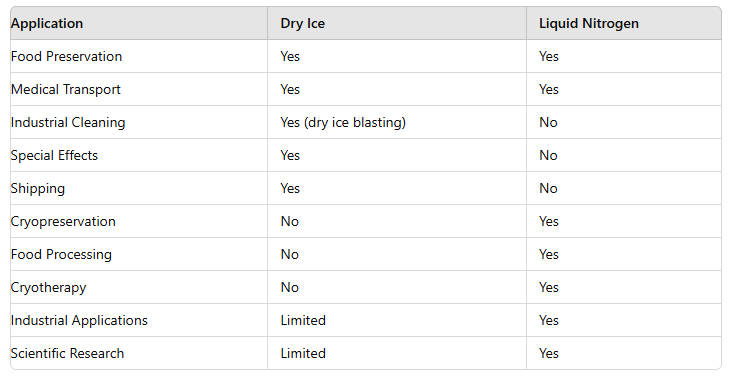

Uses and Applications

Dry Ice

Dry ice is versatile and used in a wide range of applications:

- Food Preservation: Keeps perishables cold during transport and storage without leaving any residue.

- Medical Transport: Maintains the required low temperatures for shipping medical supplies, vaccines, and biological samples.

- Industrial Cleaning: Used in dry ice blasting to clean machinery and surfaces without abrasive damage.

- Special Effects: Creates fog and smoke effects in theatrical productions and events.

- Shipping: Ideal for shipping temperature-sensitive items.

Liquid Nitrogen

Liquid nitrogen is primarily used in applications requiring extremely low temperatures:

- Cryopreservation: Freezes and preserves biological samples, cells, and tissues for medical research and fertility treatments.

- Food Processing: Flash freezes food items to preserve texture and flavor.

- Cryotherapy: Used in medical treatments to remove warts, skin tags, and other skin conditions.

- Industrial Applications: Shrinks metal components for fitting and assembly, cools electronic components during testing.

- Scientific Research: Provides cryogenic conditions for various scientific experiments.

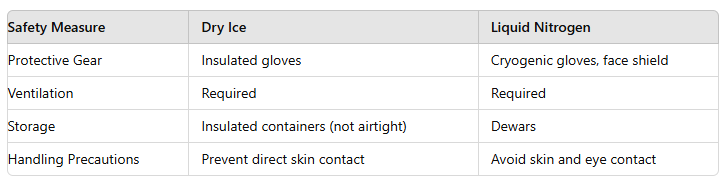

Safety Considerations

Both dry ice and liquid nitrogen require careful handling due to their extremely low temperatures and potential hazards.

Dry Ice Safety

- Handling: Always use insulated gloves to prevent frostbite.

- Ventilation: Use in well-ventilated areas to avoid CO2 buildup, which can cause asphyxiation.

- Storage: Store in insulated containers, not airtight, to allow sublimated gas to escape.

Liquid Nitrogen Safety

- Handling: Use cryogenic gloves and face protection to prevent cold burns and injuries.

- Ventilation: Ensure good ventilation to prevent nitrogen gas buildup, which can displace oxygen and cause asphyxiation.

- Storage: Store in specially designed dewars to maintain low temperatures and prevent rapid boiling.

Environmental Impact

Both dry ice and liquid nitrogen have specific environmental impacts:

Dry Ice

- CO2 Emissions: Made from recycled CO2, dry ice does not contribute to additional CO2 emissions but sublimates into CO2 gas.

- Waste: Leaves no residue, making it environmentally friendly.

Liquid Nitrogen

- Production: Produced by fractional distillation of liquid air, requiring significant energy.

- Waste: Leaves no harmful residues but needs careful handling to prevent oxygen displacement.

Choosing Between Dry Ice and Liquid Nitrogen

When deciding between dry ice and liquid nitrogen, consider the following factors:

- Temperature Requirements: Choose liquid nitrogen for applications needing extremely low temperatures (-320.4°F), such as cryopreservation.

- Residue Concerns: Use dry ice for applications where residue-free cooling is essential, such as food preservation and shipping.

- Handling and Safety: Evaluate the ease of handling and safety measures required for each cooling agent.

- Application Specifics: Consider the specific requirements of your application, such as the need for blasting (dry ice) or cryotherapy (liquid nitrogen).

Both dry ice and liquid nitrogen are valuable cooling agents with unique properties and applications. Understanding their differences, similarities, and appropriate uses will help you choose the right one for your needs.

Whether you’re preserving food, transporting medical supplies, or conducting scientific research, selecting the appropriate cooling agent ensures efficiency and safety in your operations.

FAQ Section: Dry Ice vs Liquid Nitrogen

1. Dry ice vs liquid nitrogen temperature

Dry ice has a temperature of -109.3°F (-78.5°C), while liquid nitrogen is much colder at -320.4°F (-196°C). This temperature gap makes liquid nitrogen the better choice for applications requiring extreme cryogenic conditions, such as cell preservation or metal shrinking. Dry ice, while still cold, is typically used for food shipping, fog effects, or short-term cooling.

2. Dry ice temperature vs liquid nitrogen

The temperature difference between dry ice and liquid nitrogen is over 200°F. Liquid nitrogen is significantly colder, boiling at -320.4°F, compared to dry ice which sublimates at -109.3°F. This difference affects their applications—liquid nitrogen is used when ultra-low temperatures are required, whereas dry ice is more practical for general cold storage and transport.

3. Which is better, dry ice or liquid nitrogen?

It depends on the application. Liquid nitrogen is better for ultra-cold needs like cryotherapy, scientific research, or freezing biological samples. Dry ice is better for cost-effective cooling, especially for food, shipping, or industrial cleaning. If your priority is convenience and safe handling, dry ice is often preferred. If you need deeper cold, liquid nitrogen wins.

4. What happens if you pour liquid nitrogen on dry ice?

When you pour liquid nitrogen on dry ice, both materials absorb heat from the surroundings and rapidly convert to gas—nitrogen boils and dry ice sublimates. You’ll often see intense fog or vapor as both substances evaporate simultaneously. However, there’s no violent reaction, just a dramatic release of cold gas and condensation from the air.

Clearing Up Common Questions About Dry Ice and Liquid Nitrogen

Is Dry Ice Liquid Nitrogen?

No, dry ice is not liquid nitrogen. Dry ice is the solid form of carbon dioxide (CO₂), while liquid nitrogen is the liquid form of nitrogen gas (N₂). Although both are used for cooling, they differ in chemical composition, phase, and temperature. Dry ice sublimates at -109.3°F, while liquid nitrogen boils at -320.4°F, making it significantly colder.

Is Dry Ice Nitrogen?

This is a common misconception. Dry ice contains no nitrogen. It’s made from carbon dioxide, which is a different gas entirely. Nitrogen and carbon dioxide behave differently under pressure and temperature, and their applications also differ—especially in industrial, medical, and food-grade uses.

Dry Ice in Liquid – What Happens?

When dry ice is placed in a liquid, such as water, it begins to sublimate rapidly, creating a dramatic fog-like effect. This happens because the cold CO₂ solid is absorbing heat from the liquid, turning into gas. This is often used in special effects, science demonstrations, and fog machines for events.

Nitrogen Dry Ice & Dry Ice and Nitrogen – What’s the Connection?

Sometimes people refer to “nitrogen dry ice,” but that’s a mix-up. Dry ice and liquid nitrogen are both cryogenic substances used for cold storage and transport, but they are chemically unrelated. However, in certain industrial environments, both may be used together—dry ice for transport and nitrogen for storage or experimentation—depending on temperature needs.

Which Is Colder: Dry Ice or Liquid Nitrogen?

Liquid nitrogen is colder. It boils at -320.4°F (-196°C), whereas dry ice sublimates at -109.3°F (-78.5°C). This difference makes liquid nitrogen the best choice for applications requiring extreme cryogenic conditions, while dry ice is suitable for short-term cooling and safe handling without the need for specialized equipment.

Dry Ice Calculator – Plan Your Quantity Accurately

Need to know how much dry ice you should order? Use our Dry Ice Calculator to estimate the exact amount based on your cooling duration, storage size, and temperature needs. Whether you’re shipping perishables, hosting an event, or preserving medical supplies, the calculator simplifies planning and prevents overordering or running short.

Contact Subzero Dry Ice Today

If you need expert advice on choosing between dry ice and liquid nitrogen, contact Subzero Ice Services today. Our team can provide comprehensive guidance and high-quality products tailored to your specific needs. Reach out to us to explore our offerings and discover how we can support your cooling requirements with precision and expertise.